Originally published by the Hinrich Foundation.

China is running low on clean water. A significant contributor is Beijing’s drive for technological self-reliance, especially in semiconductors, which is straining water resources. Ultimately, water shortages could even limit China’s semiconductor ambitions.

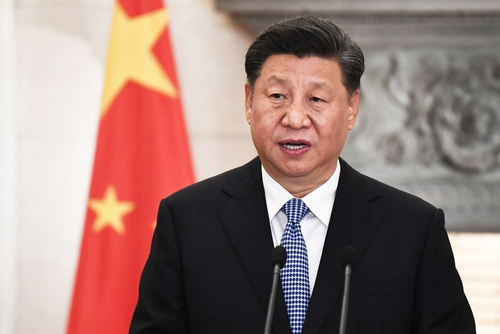

For nearly a decade, China has worked to ramp up the domestic production of semiconductors needed to make electronic chips. This supports the goal that President Xi Jinping has set to establish the People’s Republic of China as a leading power in global science and technology by 2049, the 100th anniversary of its founding. Though today China accounts for nearly three-quarters of global demand for semiconductors, Chinese plants only produce about 15 percent of the world’s output, largely of lower-end commodity chips.

Since 2016, the United States has implemented a policy to block China’s access to advanced foreign chip technology and its ability to produce them at home. In October 2022, this culminated in a set of new restrictions on exports of advanced chips to China to prevent their use in military technology. The clampdown expanded in August 2023 with restrictions on US investments in China in sensitive technologies like semiconductors.

Almost a decade before these export controls were imposed, the Chinese government began allocating massive subsidies—more than $46 billion—to develop semiconductor technology. With the imposition of sanctions on the Chinese semiconductor sector, Chinese companies are now seeking to switch to domestically made components, even for chips that are not subject to Western controls. A new infusion of funds will add another $40 billion to China's effort. But before we get too alarmed about China as a future semiconductor competitor, it’s worth examining a major overlooked constraint on the sector’s development in China—water, or rather the lack of it.

The Semiconductor Water Problem

Enormous quantities of ultrapure water are needed in semiconductor production. A semiconductor plant, known as a fab, typically requires about 5 million gallons per day, and 10 million for large foundries, equivalent to the consumption of 300,000 households. The water must be processed so that all impurities are removed before it is used to rinse each chip and remove contaminating debris.

China faces a geographic mismatch in terms of the location of the water supply and demand. Water is most abundant in the southwest of the country, but the areas with the greatest demand are in the north and east coast, where water quality is poor. The north, where some of these fabs are located, is challenged both by high water demand from agriculture and industry and by water pollution. Though Chinese leaders recognize the challenges that water scarcity and water pollution pose and have taken measures to address them in recent years, water-intensive economic priorities like the development of the semiconductor sector typically are set without regard for available resources or competing demands on them.

Unsustainable industrial processes contribute to the problem. Other countries that face water stress reuse a much higher percentage of the water involved in semiconductor production. Taiwan recycles nearly 85 percent of the water used for semiconductor production. But China recycles a relatively small amount of the water used in fabs. One study found that Chinese fabs used three times more water than US plants in the rinsing process and power generation. By some estimates, China’s semiconductor sector accounts for 27 percent of the country’s total industrial water use.

China’s top 10 semiconductor firms are located in places with water challenges. Take Semiconductor Manufacturing International Corporation (SMIC), China’s largest chip producer. SMIC’s main locations are all in areas with high water stress. And a new SMIC plant is being built in Tianjin, the city with the lowest availability of water per capita in China.

Pollution and Climate Change Add to China’s Water Woes

Pollution of groundwater also remains a serious problem, despite a policy effort to improve water quality in China. In 2022, the percentage of groundwater unsuitable for industrial use increased from 20.6 to 22.4 percent, according to China Water Risk, a Hong Kong nonprofit.

Even in areas that traditionally had adequate water, climate change has led to drought. For example, the central China city of Wuhan, where China’s state-owned Yangtze Memory Technologies Corporation was founded in 2016, has typically been subject to flooding. It was designated a “sponge city” a decade ago for experimental approaches to drainage. In 2022, however, Wuhan and other cities along the Yangtze River basin experienced the worst drought since modern records began in the 1960s. In what should have been the wet summer season, the river fell to levels not usually seen outside the end of the dry winter season. Semiconductor firms complained that energy shortages, caused by disruptions to hydropower plants, adversely affected their production.

Since ancient times, Chinese leaders have seen water management as central to their governance and mandate to maintain social stability. Xi is no exception, as the recent publication of In-Depth Study and Implementation of Xi Jinping's Important Discussions on Water Control attests. Xi set goals to create an “ecological civilization” and lead “a global green industrial revolution,” but climate change creates an unpredictable environment that resists his efforts at control. Xi has continued and enhanced a massive state project to divert water domestically to its parched areas, but such infrastructure solutions do not address deeper issues of inefficient and unsustainable water use.

It is a great irony that many of the thirsty chips the semiconductor companies produce will be used to power green technologies such as wind turbines, solar panels, and electric cars. Yet the fabs that produce the chips not only compound China’s water scarcity, they also require a lot of energy and generate large quantities of greenhouse gases. The enormous investments in the semiconductor sector in China highlight Beijing’s priority of technological self-reliance, but they come at a high environmental cost.

This article was edited for length from the original.